Components of the Ford CDP

| Created | |

|---|---|

| Tags |

The Ford CDP (Consolidated Delivery Platform) is a platform designed around the existing concept of consolidated delivery. The CDP adapts Ford commercial vehicles to this new way of delivering, with a set of different assets.

The Philosophy behind the CDP

As mentioned before, the CDP is a system that strives to seamlessly integrate the different components throughout the delivery chain. To allow the aforementioned flexibility and seamless transitions between links in the chain, the system relies upon two main components: the CDP modules which act as containers to unify the packages and the new vans that will act as mobile distribution centres.

The CDP Module(s)

As the name hints, consolidated delivery relies on bringing packages together (consolidation) for distribution in one go. Packages for a single address or multiple joint addresses have now to come together in the distribution centres and be shipped in flexible schedules, at the client's convenience.

This means new ways of sorting and distributing the packages inside the warehouses are needed, for volumes that suit effiecient delivery, as well as adaptability to different means of transportation. Transportation that is allowed access to new pedestrianized urban areas.

There are three different sized modules.

The CDP Adapted Vans

To ensure that the modules can easily be loaded onto vans and transition down the logistic chain, they are easy to attach and detach and load into whatever means of transport will be used for the last-mile, whether it is a pedestrian courier or a cargo bike. The CDP is designed for transitions on the go, with a signalling code that communicates to messengers which module they have to take and where to drop off the returns.

Vans also have special RFID sensors which recognise approaching messengers, and turns on the correct set of lights. First to indicate to the messenger that they have successfully been detected by the van and, secondly, guide the module pick up.

The CDP Signalling Device

The final piece of the puzzle is the set of signals which will help the different parts of the chain to work together in a much more streamlined fashion. The goal is to optimise swift transitions since time stationary is lost time delivering. To do so, the van drivers and messengers have to wear a device which allows visual and haptic signalling.

For messengers, it signals when a van is nearby, whether it is the correct one and whether they have been successfully detected; so they know that the van driver is aware of their presence and will be stopping. For the van driver, it notifies that a messenger is nearby and that they have to stop for a swift drop-off.

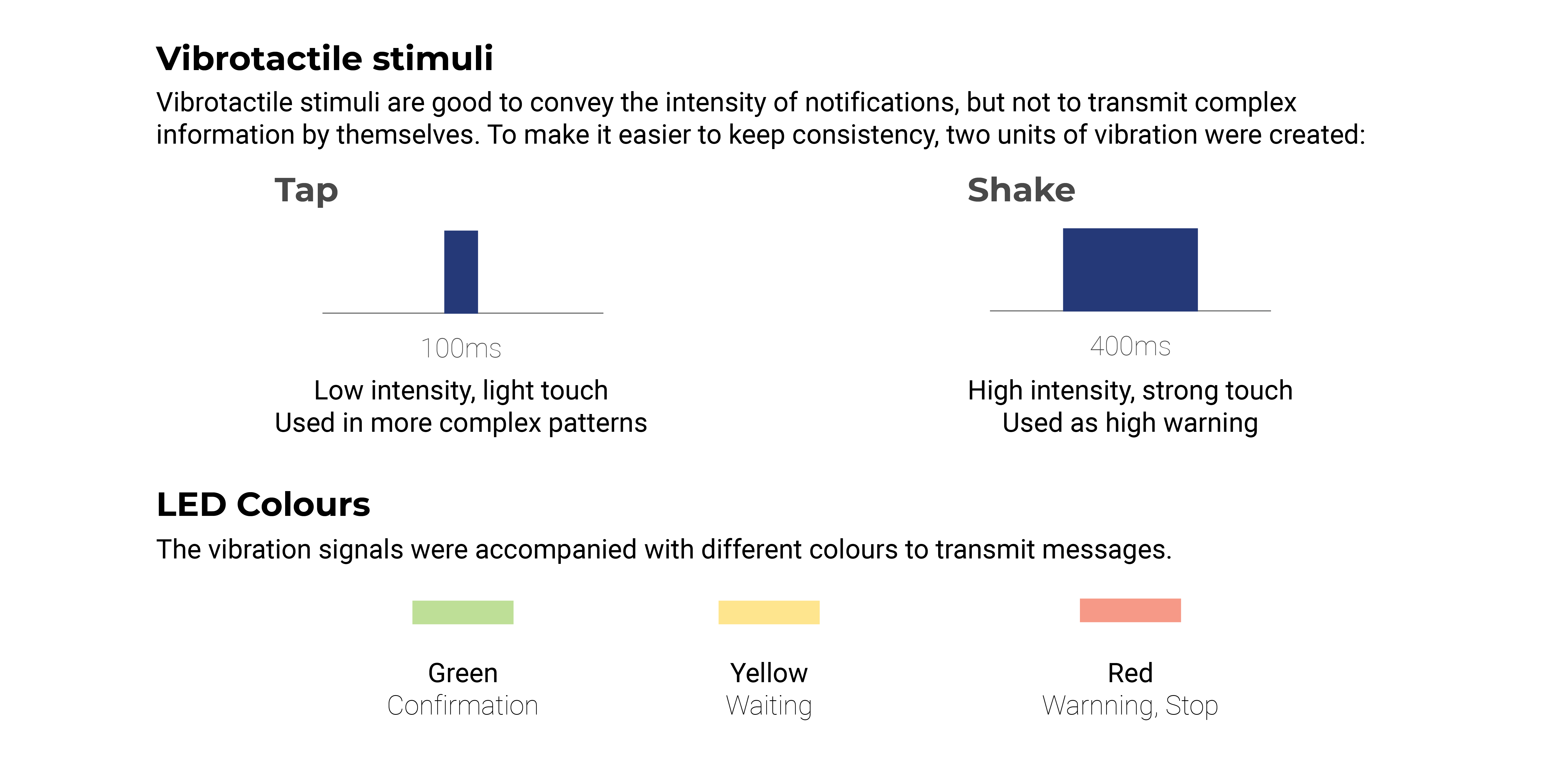

To give all this information, the device will use visual and haptic signals. Vibrotactile cues (cues are given by a vibration motor) were found insufficient to convey complex information, but were found really useful as triggers and to convey the intensity of the signal.

This system was designed with a possible autonomous future in mind, where the messengers interact with autonomous vehicles. This allows the van to transmit information to the messenger on what their actions are and what behaviour to expect from the van.

Future Improvements & Development

There are some other parts of the system that still need further development. These ideas come from the backlog since the project started, the last prototyping, exploratory sessions and from conversations held with bike messengers. As the list is really extensive, it is quite clear that there is a lot to be explored and learned still, especially in practical and technical matters.

Module Size

Dimensions and proportions of Modules

The module that was prototyped showed the team the dimensions of the medium-sized module. Having seen how it actually feels and looks, the team suggests that a change of proportions may be needed, as it may be a bit taller than it needs to be. It would also be necessary to see how the different modules fit other means of transport, as the team did not have access to those during the final stages of prototyping.

Handle balance and rail ergonomics

As the prototype was not of the envisioned materials and the dimensions were not tested until the end of the project, the load distribution and the handle position were not tested. It could be interesting to see how that will work, as a basic ergonomic study has been conducted, but in a very superficial way. Doing this is especially relevant for the large modules.

The team would have also liked to test how the system adapted to the different vehicles that the client has available, as it would be nice to see where the racks for the packages would be located in a real van. This is a necessary step to really understand the ergonomics of the entire loading and unloading system.

Module Features

Module opening mechanism & NFC tag

As seen in the recent Apple keynote, some industries are advancing towards the use of NFC to handle the locking of, for instance, cars. Couriers using cargo bikes told the team that one of their concerns during their work day is the safety of the packages they have to leave waiting while finishing a delivery. A NFC powered mechanism for locking the modules could be an interesting proposal to be implemented in the system.

NFC tags are also useful to get information when scanning them, like addresses or information of the package. Tags were added to some prototypes during the development of the project to test this functionality, but the real potential is still to be discovered as the team had a very basic knowledge on how to program them.

Module materials

Something that was not addressed during the project is the material of the modules. The main requirement is that the material has to be sturdy, shock resistant and weather resistant as the modules are loaded outside the van. They also need to be structurally sound, so they can hold in the rail, which could require some reinforcement. At the end of the day, a composite or reinforced plastic would be the suggested ones.

The messengers the team has talked with also suggested softshell materials with a sturdy structure to optimise space and some kind of collapsible structure so the modules can be adapted to different loads or be stored more efficiently.

Module storage

Given that distribution centres will have to hold a proportion of different sized modules, there is a need to effectively store them. This has not been explored during the project but it could make sense to be explored, as some kind of collapsible structure would save an important amount of space. This would also be the case for the consumers storing them somewhere in their homes.

Wearables and special features

Possibilities of the wearable

The wearable used for testing and prototyping used a microcontroller and some electronic components to give signals, but wearable devices with screens can convey much more information and be used in many different ways. The team has not explored those possibilities, but it could be worth exploring them in the future. With the current functionality, regular of the shelves smartwatches could probably suffice, reducing the need to develop a dedicated wearable.

Autonomous, pedestrian and bicycle courier systems

Cargo bikes are the most used example as it is quite clear how they can transport the different modules, but the system is supposed to work for all kinds of couriers, so maybe special transportation devices could be designed to make it more comfortable and safe to deliver bigger modules in other means of transport, like bicycles. An exploration in this direction was made back in the first exhibition, attaching the module magnetically to a backpack frame.

There have also been explorations of autonomous vehicles capable of delivering packages for small distances within cities. These could also be implemented in the framework, being able to carry the modules for the last mile.

Dedicated modules

As the system starts adapting to the needs of different services, some modules could be made especially for certain tasks, like the transportation of refrigerated or frozen goods or special loads. This would change some of the technical specifications of the modules.

Other matters

Software

The complexity and the number of variables to make this system work is pretty significant, and as different messengers expressed, the software currently used by delivery companies cannot handle these kinds of tasks at the moment. This is a project meant to be deployed in 2030, so software and processing power will have increased significantly, but the integration of all the features and stakeholders is still a very complex task.

Autonomous vehicles

Autonomous vehicles were regarded at the beginning of the project as the biggest threat for couriers and as they rise in relevance, couriers will eventually be overshadowed by vehicles that can follow routes on their own. Changing the vans with autonomous vehicles is still a possibility, but 2030 is close enough not to have fully autonomous vehicles, yet. The idea behind the racks and modules can be taken to autonomous delivery vehicles with no problem and the signalling system allows communication from the van to the messenger.

Aerial deliveries

Even further into the future, drones and other unmanned aerial vehicles (UAV) are a plausible new way of delivery. For drone delivery, a consolidated approach makes a lot of sense, as reducing the number of flights is a significant advantage.

The modules could be of great use in this case, as drones could be fitted to be able to carry them and maybe picking them up on the go. The vans will act the same way as in the envisioned concept, but servicing the UAV fleet.

Press the link below to go back to the homescreen:

Ford Consolidated Delivery Platform

Ford Consolidated Delivery Platform

Special thanks

Jaime Pintado

For great feedback and enthusiasm about the project and responding all our questions!

Juan Latorre

For patience from the beginning till the end, and giving honest opinions, insights and feedback!