Ford Jupiter

| Abstract | Some aspects of our lives will remain the same by 2030, but many others will experience changes that will affect many of the sectors involved in big cities. This is the case of delivery which will suffer an exponential increase, receiving a package will be part of our daily routines. Ford Jupiter is designed for this social context, introducing automatic processes to guarantee the highest efficiency, but at the same time keep humanity in the delivery ecosystem. |

|---|---|

| Group | 26 |

| Students | Núria Nicolau i Torra, Ashley Hemerik |

| Client |  Ford Ford |

| Brief | Courier?s Companion |

| Coach |  Daniel Shor, Daniel Shor,  Wouter van der Hoog Wouter van der Hoog |

| Morning Exhibition Time | |

| Exhibition Video Channel | https://tudelft.zoom.us/j/5982430072?pwd=cUIvcit6cVJXT3lpcnEvRVhaeWQ0dz09 |

| Afternoon Exhibition Time | |

| Live Status | Closed now ? |

??To join our Zoom Channel use the password: jupiter

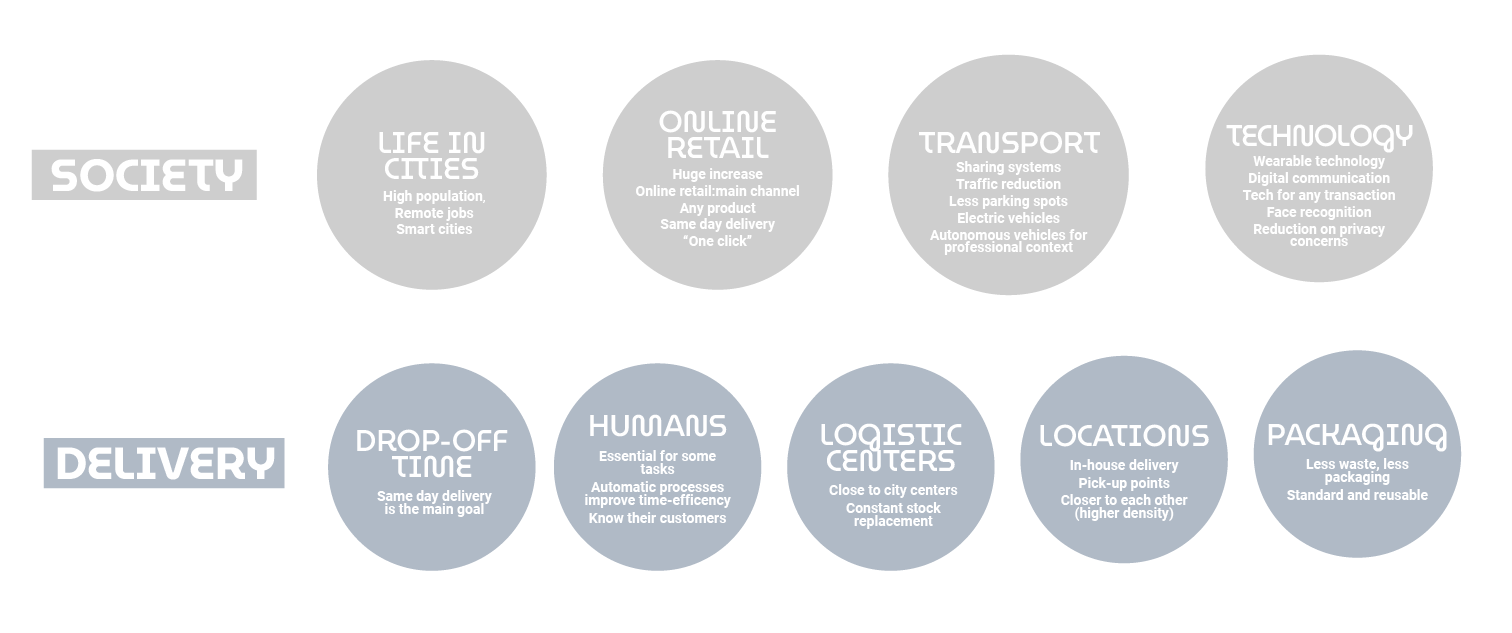

Year 2030

The first section is dedicated to contextualize Jupiter, the delivery truck for 2030

Understanding and "scanning the world" by 2030 has been essential to contextualize Jupiter. Life in big cities will change, mainly influenced by the increase of sustainability regulations and introduction of technology in our lives. Delivery will also change ten years from now, specially by suffering a huge increase, becoming one of the main economical sectors. Receiving packages will become part of our routines, anything would be available in just one click, purchased from anywhere at any time.

Project goal

Increase efficiency while keeping humanity

Delivery system

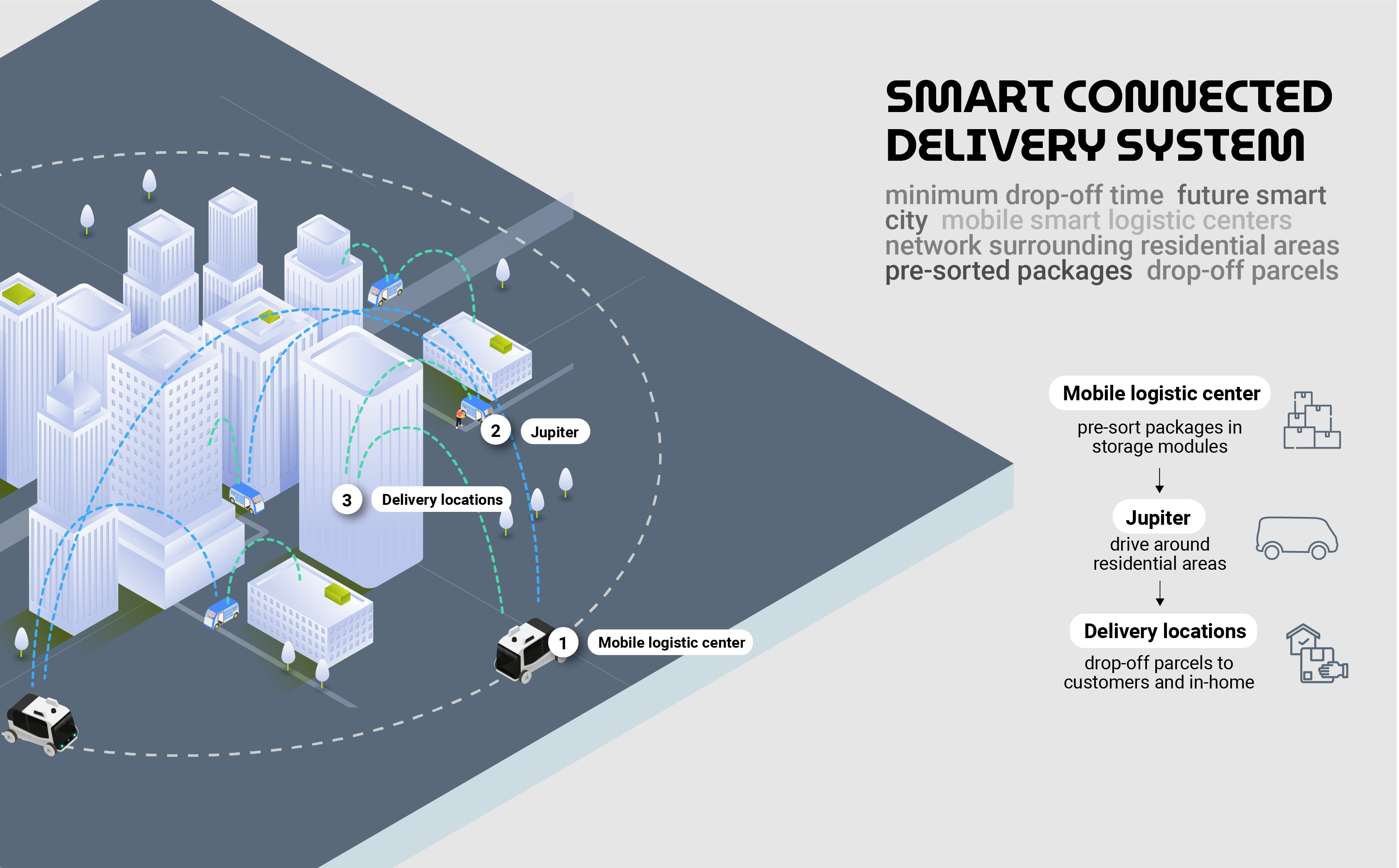

This section focuses on explaining the complex delivery system from which Jupiter is a key element

Ford Transit 2030 is part of a bigger delivery system, ideated for 2030's context requirements. This system involves all the agents: logistic centers, delivery trucks, couriers and drop-off locations.

The whole system is based on efficiency, by connecting the different parts, optimization can be achieved, resulting in reducing drop-off times.

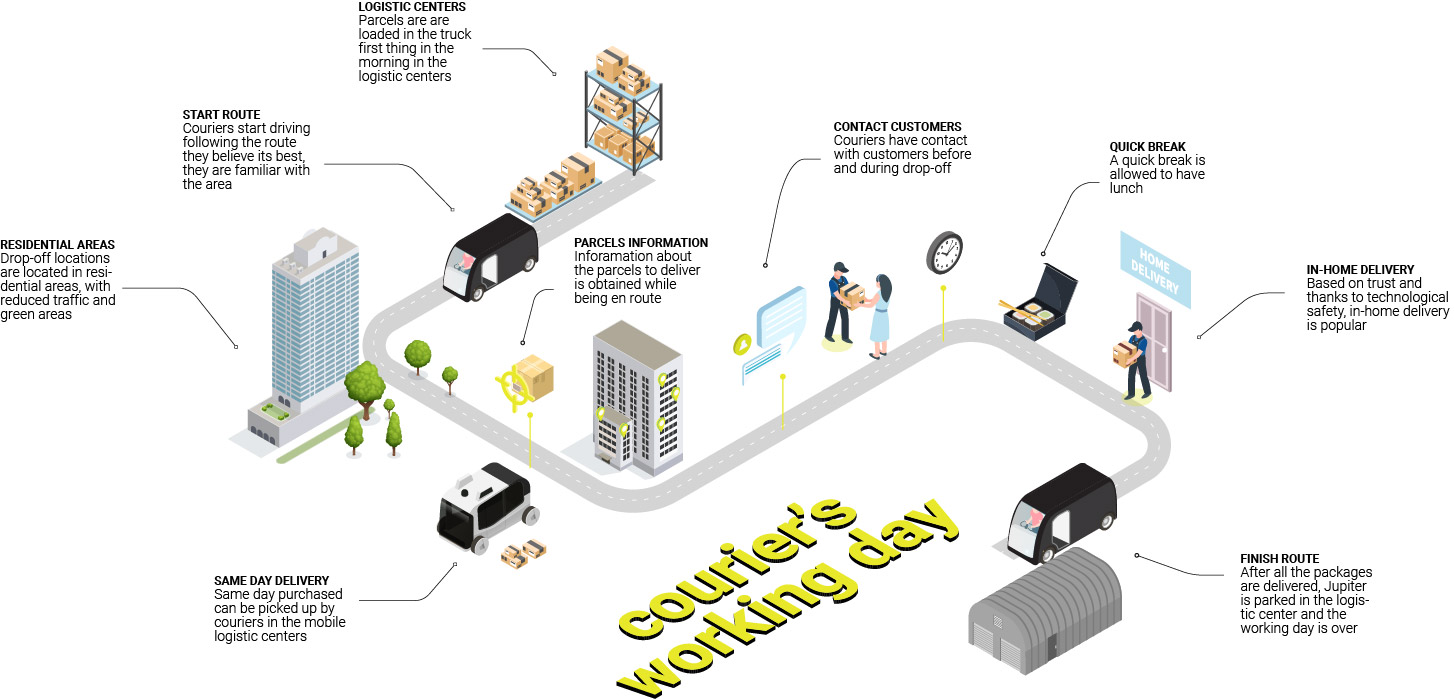

Persona

How does a working day look for Gregg?

Jupiter

In this section Jupiter, our concept, is explained in more detail.

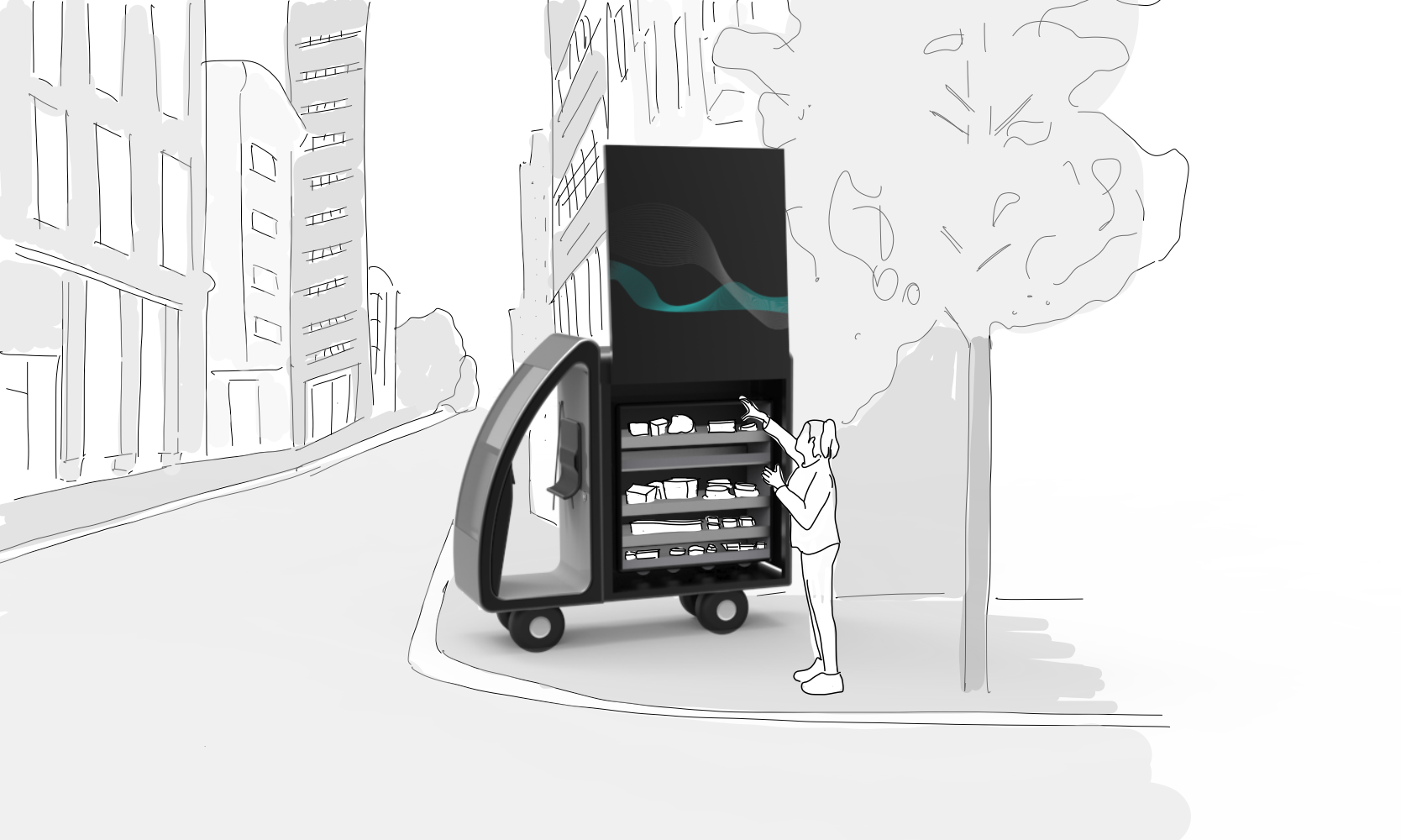

Ford Jupiter is a truck designed for delivery in urban areas. It is formed by two parts, the vehicle itself and the storage modules that contain the packages, which are placed in the back part of Jupiter. Since reducing drop-off time has been the main challenge, the hop on/off concept has been chosen, in order to guarantee the maximum efficiency during delivery. However, there's other relevant areas that have been considered while conceptualizing Jupiter due to their direct impact on efficiency and courier's role.

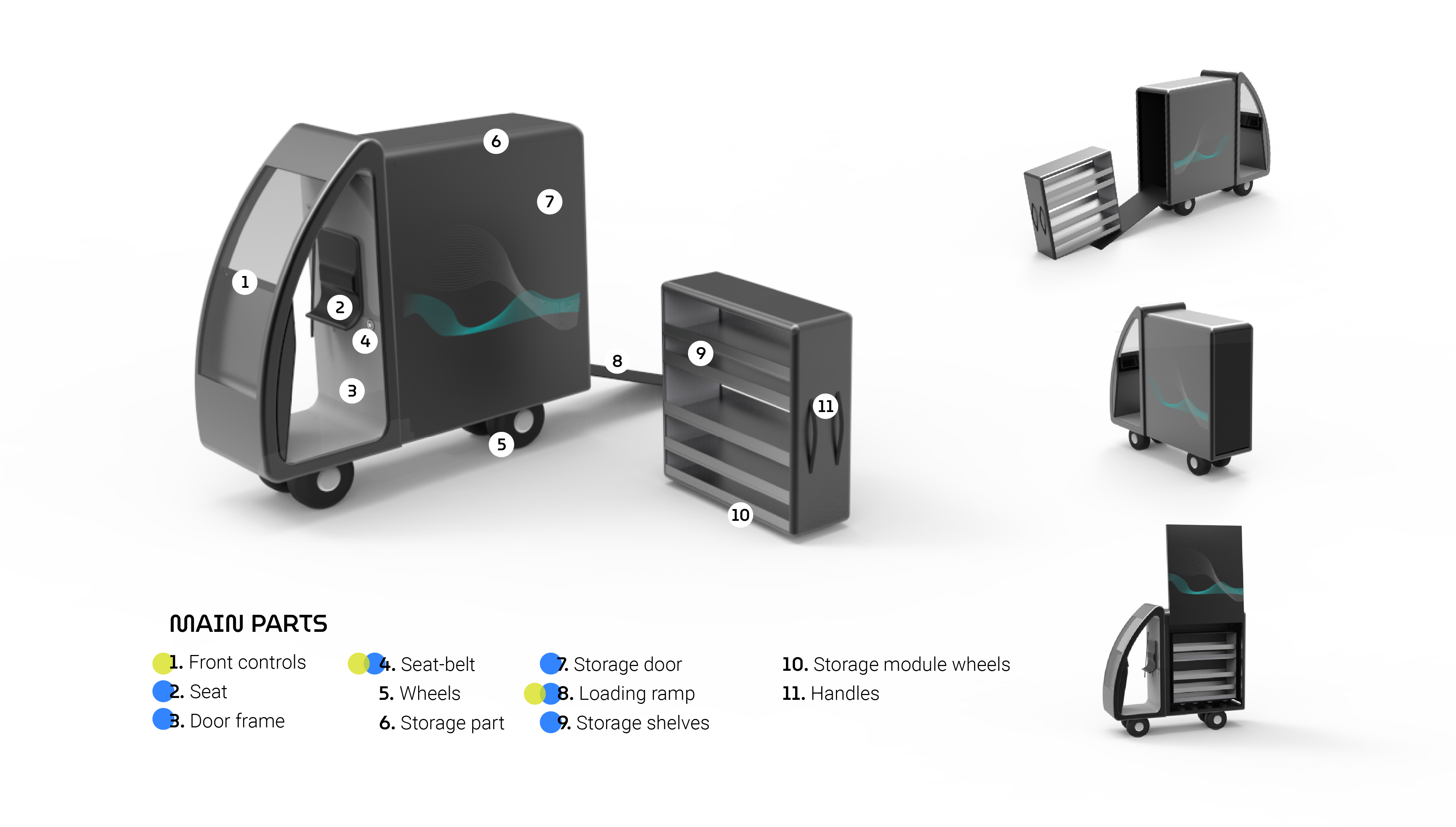

Parts

1. Front controls

The courier still drives the vehicle themselves and they are allowed to decide their own routes. The cockpit is designed to help with tools like a GPS, customer info, automatic lights and standby control, and much more.

2. Seat

Driving in a semi-standing position improves the efficiency when having to leave the vehicle many times in a shift. The seat is designed like a bus-station sitting bar, allowing the courier to rest while also making getting up a minimal effort.

3. Door frame

There is no door to allow entering and leaving the vehicle fast and safely, by having a wide and low frame, this is enhanced.

4. Seat-belt

To guarantee couriers' safety, a seat-belt is introduced, even-though some legislations allow not wearing it for short distances between drop-off locations. Ford Jupiter has a magnetic seatbelt lock that unlocks automatically and you can put on really quickly.

5. Wheels

The wheels are low to the ground to make getting in and out easier, they are also close together to make the turning circle very small for maximum maneuverability in a dense city.

6. Storage part

This is where the storage modules are being kept, they lock with the Jupiter to prevent shaking while driving.

7. Storage door

The storage doors open automatically when the courier is ready to get a package, and closes when the courier is driving or when he's not close to the vehicle. It opens upwards so that they can also be opened on narrow sidewalks.

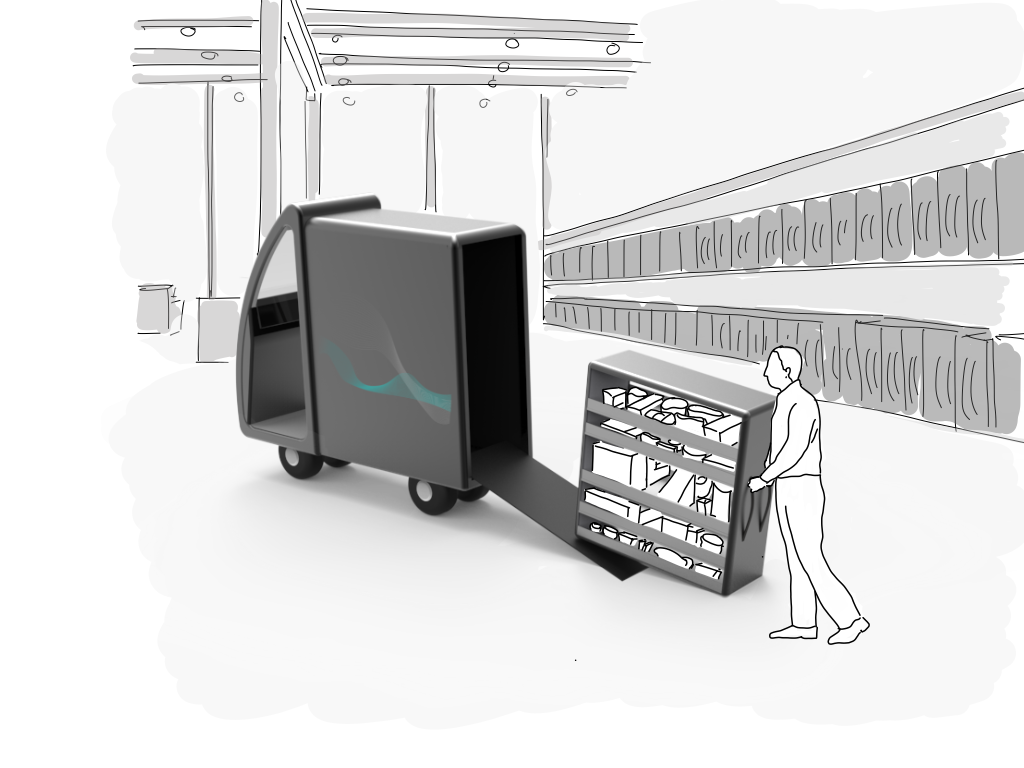

8. Loading ramp

The back door of the storage part is also a ramp for the storage modules to be pushed up on

9. Storage shelves

The storage shelves in the module are themselves modular, they fit into slots so you can choose how much room there is on a shelf and how many shelves there should be in a module.

10. Storage module wheels

There are small wheels under the storage module to make moving them easier. However, once it's introduced in the truck, it's fixed thanks to a locking system.

11. Handles

The handles indicate which side is forward and which side is not. On the other side is the mechanism to lock the module with the Jupiter

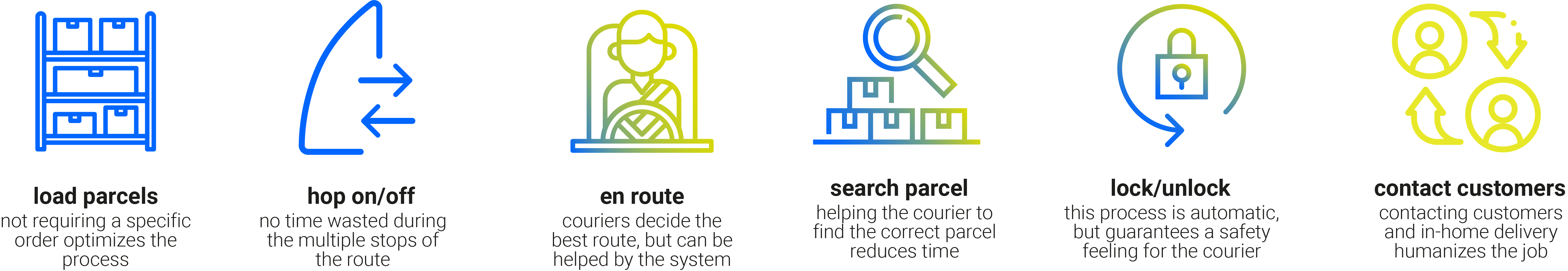

Jupiter in-depth: interactions

In this section some of the interactions that occur during the main steps of the delivery process are shown.

1. Loading the parcels

In the new parcel delivery ecosystem, the storage modules are loaded with parcels inside a storage depot. A computer calculates how to optimize space in the modules, so that a storage module can fit as many parcels as possible.

These locations are remembered and sent to the vehicle, so it knows which location to highlight later when the courier wants to pick up a certain package.

2. Starting the route

During a working day, an average of 150 packages are delivered per courier. This means that couriers need to stop and re-start their routes multiple times, not losing time here is essential. Entering the vehicle and starting to drive again needs to be done safely and quick.

Check this interactive prototype to see how this process goes and know better Jupiter's driving controls.

3. Get parcels to deliver

When the courier stops their Jupiter and it is close to a drop-off location, the front display indicates the package to deliver and the storage doors open automatically. In the storage module, a laser pointer indicates which packages the courier should pick up to deliver, determined by GPS location.

4. Locking and unlocking Jupiter

Locking and unlocking Jupiter is done automatically thanks to a proximity sensor integrated on a the couriers' wrist wearable. Visual elements display the locked state of the vehicle.

5. Route real-time information

The display integrated on the front window provides information in real time so that delivery men can make decisions and be prepared before arriving to the delivery location. Interacting with the screen is mainly done by touch and voice control.

Information displayed:

- ? Map with drop-off locations

- ? Customers availability (green: YES / red: NO / grey: UNKNOWN)

- ? Contact customers

- ? Road state

- ?? Parking recommendations

- ? Time recommendations

- ? Next parcel to deliver: what and where in the storage module is located

Decide route

Couriers get to decide the route they want to follow, based on their experience and knowledge. When arriving to a drop-off location, information about the parcel to deliver is obtained.

You're the courier now, click on the arrows to decide the next customer.

Voice control

The front display can be operated by voice, this improves safety and provides couriers with information about the route, which can help them optimize it.

You're the courier now, click on the icons to see how you'd interact with Jupiter